What are ER Collets?

ER collets are used on CNC spindles. Different sized spindles have their own collet size. Typically the bigger the spindle (power and size) the bigger the ER collet. For example, 3DTEK sell spindles with a 65mm body diameter 1.5kW <3kg with an ER11 collet. Also, 80mm body diameter 1.5kW 5kg with an ER16 collet and Finally 80mm body diameter 2.2kW, 5.3kg with an ER20 collet. See the trend? We found this handy table below to show the trends and shank diameters endmills you can use with ER collets:

| Size | Range (in) | Range (mm) | ER-11 | ER-16 | ER-20 | ER-25 | Metric ER-25 | ER-32 | Metric ER-32 | ER-40 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/32″ | 0.020—0.039″ | 0.5—1.0 mm | 4797 | 4613 | ||||||

| 1/16″ | 0.039—0.079″ | 1.0—2.0 mm | 4601 | 4614 | 4620 | 5053 | 4558 | |||

| 3/32″ | 0.079—0.118″ | 2.0—3.0 mm | 4398 | 4615 | 4621 | 5054 | 4332 | 4559 | 4333 | |

| 1/8″ | 0.118—0.157″ | 3.0—4.0 mm | 4454 | 4434 | 2443 | 5055 | 4332 | 4560 | 4333 | 5885 |

| 3/16″ | 0.157—0.197″ | 4.0—5.0 mm | 4455 | 4435 | 4622 | 5056 | 4332 | 4561 | 4333 | 5886 |

| 7/32″ | 0.197—0.236″ | 5.0—6.0 mm | 4399 | 4616 | 4623 | 5057 | 4332 | 4562 | 4333 | 5887 |

| 1/4″ | 0.236—0.276″ | 6.0—7.0 mm | 4456 | 4436 | 2444 | 5058 | 4563 | 5888 | ||

| 5/16″ | 0.276—0.315″ | 7.0—8.0 mm | 4617 | 4624 | 5059 | 4332 | 4564 | 4333 | 5889 | |

| 11/32″ | 0.315—0.354″ | 8.0—9.0 mm | 4619 | 4625 | 5060 | 4565 | 5890 | |||

| 3/8″ | 0.354—0.394″ | 9.0—10 mm | 4618 | 2445 | 5061 | 4332 | 4566 | 4333 | 5891 | |

| 13/32″ | 0.394—0.433″ | 10—11 mm | 4626 | 5062 | 4567 | 5892 | ||||

| 7/16″ | 0.433—0.472″ | 11—12 mm | 4627 | 5063 | 4332 | 4568 | 4333 | 5893 | ||

| 1/2″ | 0.472—0.512″ | 12—13 mm | 4628 | 5064 | 4569 | 5894 | ||||

| 17/32″ | 0.512—0.551″ | 13—14 mm | 5065 | 4332 | 4570 | 4333 | 5895 | |||

| 9/16″ | 0.551—0.591″ | 14—15 mm | 5066 | 4332 | 4571 | 4333 | 5896 | |||

| 5/8″ | 0.591—0.630″ | 15—16 mm | 5067 | 4332 | 4572 | 4333 | 5897 | |||

| 21/32″ | 0.63—0.669″ | 16—17 mm | 4573 | 5898 | ||||||

| 11/16″ | 0.669—0.709″ | 17—18 mm | 4574 | 4333 | 5899 | |||||

| 23/32″ | 0.709—0.748″ | 18-19 mm | 4575 | 5900 | ||||||

| 3/4″ | 0.748—0.787″ | 19—20 mm | 4576 | 4333 | 5901 | |||||

| 13/16″ | 0.787—0.827″ | 20—21 mm | 4578 | 5903 | ||||||

| 27/32″ | 0.827—0.866″ | 21—22 mm | 5904 | |||||||

| 7/8″ | 0.866—0.906″ | 22—23 mm | 5905 | |||||||

| 15/16″ | 0.906—0.945″ | 23—24 mm | 5906 | |||||||

| 31/32″ | 0.945—0.984″ | 24—25 mm | 5907 | |||||||

| 1″ | 0.984—1.024″ | 25—26 mm | 2908 |

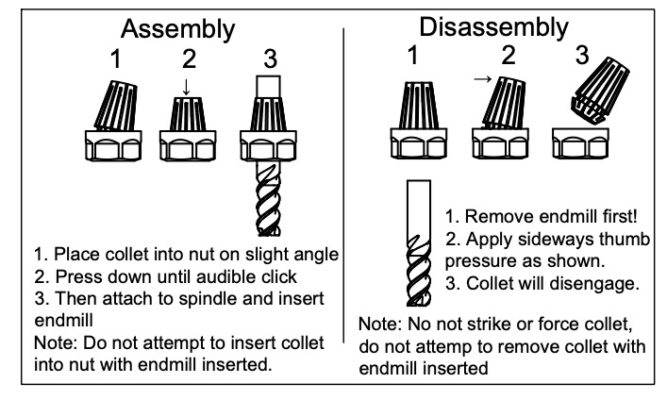

How to use an ER Collet?

IMPORTANT NOTE:

Always keep your collets clean and free of debris. They will not crush evenly with debris build up in the slots. Do ensure you blow out (air line or other) the male and female thread (spindle and nut) as swarf or debris will damage the thread and replacing the spindle shaft is not cheap!!

We hope you found this post useful. Sign up to our newsletter or Social media channels.

Thanks for reading

–3DTEK